Sodium Hypochlorite Generator from Brine electrolysis

chlorine making system adopts advanced electrolysis techniques.

Sodium hypochlorite solution can be produced on spot via electrolysis of brine

water that is used to substitute highly-toxic liquid chlorine and chlorine

dioxide disinfection system and hence is widely applied in domestic and

overseas large and medium-sized water plants. Its safety and superiority is

getting approval from an increasing number of customers. The equipment can

satisfy disposal of life drinking water less than 1 million tons per hour.

Effective density of chlorine 0.6-0.8% Intake

pressure: 0.2-0.4MPa Salt

consumption: 3.5kg/kg Cl2

Direct current drain: 4.2kW/kg Cl2 Water

drain: 125L/kg Cl2

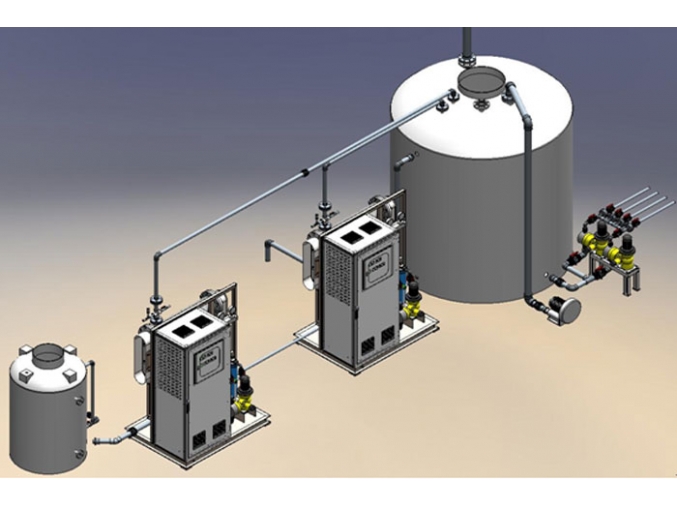

Technique Explanation

Pure water→salt

dissolving tank→booster pump→salt mixture→precision filter→electrolytic

cell→sodium hypochlorite storage tank→measurement pump

Equipment Configuration

1.

Compound titanium electrode: ruthenium and iridium coat layer, duration: 5

years

2.

Tubular electrolysis tank: with its transparent barrel designing, it can help

observe operating conditions of electrode.

3.

Frame: carbon steel spray lacquer epoxy zinc-rich bottom, intermediate coat,

metal fluosol perfluorocarbon painting, varnish 250μm

4.

Pipeline: UPVC pipeline, Taiwan Huanqi

5.

Product storage: FRP

6.

Electrical appliance: Siemens or ABB PLC, electric appliance Schneider

Characteristics

1.

The equipment can realize automatic operation and is secured and reliable;

2.

It averts usage and transportation of highly-toxic chemicals, eradicates damage

of toxic chemicals on the environment, operation staffs and surrounding

residents and protects both the environment and mankind.

Application

Tap water plant disinfection,

disinfection of municipal sewage, food processing, oil will disinfect water,

hospitals, power plant cooling water disinfection.

Specification

Yield of active chlorine of

seawater electrolysis sodium hypochlorite system can be made following

customers’ requirements. The table only reveals standard model of the company.

|

Model

|

Chlorine

production

(g/h)

|

Available

chlorine concentration

|

Flow

(L/h)

|

Water

consumption

(m³/d)

|

Salt

consumption

(kg/d)

|

DC

power consumption

(kWh/d)

|

Power

supply

(V)

|

|

CSD100

|

100

|

0.6-0.8%

|

12.5-17

|

0.3

|

7.2

|

9.6

|

380/415/440

|

|

CSD

500

|

500

|

0.6-0.8%

|

62.5-83

|

1.5

|

36

|

48

|

380/415/440

|

|

CSD

1000

|

1000

|

0.6-0.8%

|

125-167

|

3

|

72

|

96

|

380/415/440

|

|

CSD

2000

|

2000

|

0.6-0.8%

|

250-333

|

6

|

144

|

192

|

380/415/440

|

|

CSD

5000

|

5000

|

0.6-0.8%

|

625-833

|

15

|

360

|

480

|

380/415/440

|

|

CSD

10000

|

10000

|

0.6-0.8%

|

1250-1667

|

30

|

720

|

960

|

380/415/440

|

More

details, please contact:

Email: info@cosuppliers.com

What’s

app: 8617828431369